|

Pretreatment system

Different pretreatment equipment is

needed for flexible and bulk materials.

|

|

Feeding system

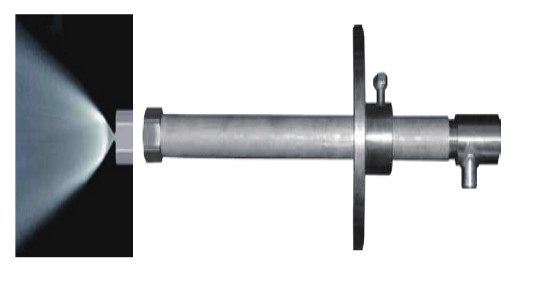

Design the quench tower according to gas flow modelling, then select and place spray guns. Select imported two fluid cooling spray guns and an automatic quenching control system; ensure the effectiveness of quenching so that “over-cooling” and “under-cooling” does not occur.

|

|

|

Feeding system

Select different feeding methods to

meet the different physical properties of

liquid, solid and semi-solid materials.

|

|

Flue gas treatment system

The selection or combination of various treatment processes can achieve long-term and stable discharge of NOx, SO2, HCl and dust. The selection of European formula refractories, the selection of pipeline anticorrosion materials and the installation of cement tortoise shell net for dust collector equipment also provide a guarantee for the long-term continuous operation of the incineration system.

|

|

|

Pretreatment system

The use of highly efficient feeder sealing technology, rotary kiln sealing type

and water sealing slag seal, combined with adjustable combustion air

supplement, achieves oxygen-rich and controlled oxygen combustion, so that

the thermal action reduction rate is less than 5%, and harmful substances are

completely incinerated.

|

|

Control system

The application of PLC or DCS improves the automation level of incineration

line operation, improves the stability and safety of system operations, and

saves on labor costs. In addition, the setting of infrared thermal imaging and

Emergency Stop Device (ESD) ensure the safety of the system.

|

|

|

Waste heat boiler

The selection of a full-membrane wall boiler with high efficiency and avoiding blockage can adjust the fluctuation of hazardous waste |

|